Wy use a wire rope

Tension

A rope can be a hauling respectively a tensile element / a rope cannot take over any pressure!

By means of a rope one can change the direction of a force (using a sheave)

By means of a rope one can transform a rotating movement to a linear one and vice versa. (using a winch or just a friction sheave)

Suspension

A rope can be used to suspend other elements

To suspend a track

To be a track

Combined functions

Suspending and hauling

Conclusion: There is no other „element“ or „subsystem“ able to adequately take over all the functions a steel wire rope normally does!

A wire rope should be able to take over high tensile forces be flexible be a safe sub system Explanation why a rope takes over high tensile forces, why it is flexible and why it is safe What are the potential problems with the wires with high grade, what do we have to take care of? Some further demands Mention the contradiction among the different demands

A wire rope should be able to:

take over high tensile forces

be flexible

be a safe sub system

Explanation why a rope takes over high tensile forces, why it is flexible and why it is safe

What are the potential problems with the wires with high grade, what do we have to take care of?

Some further demands

Mention the contradiction among the different demands

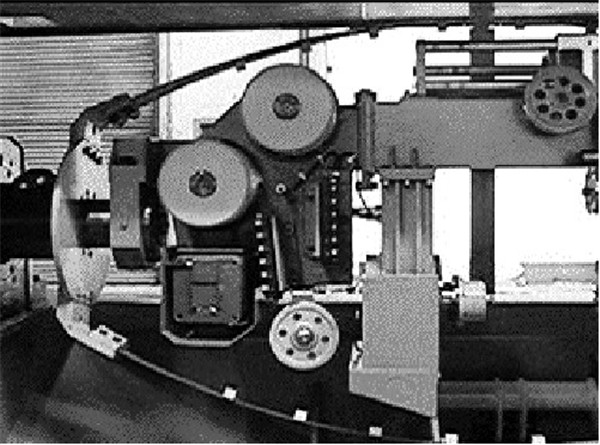

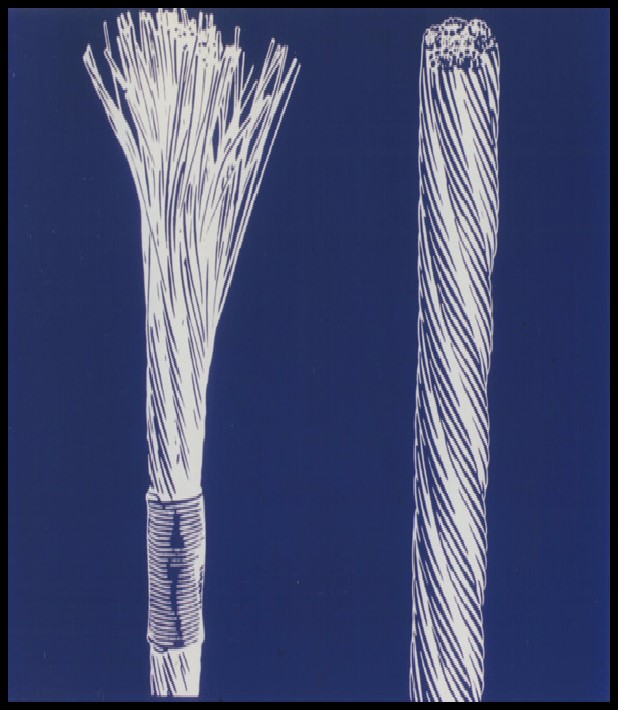

Wire rope manufactoring

First step is to spool the wire.

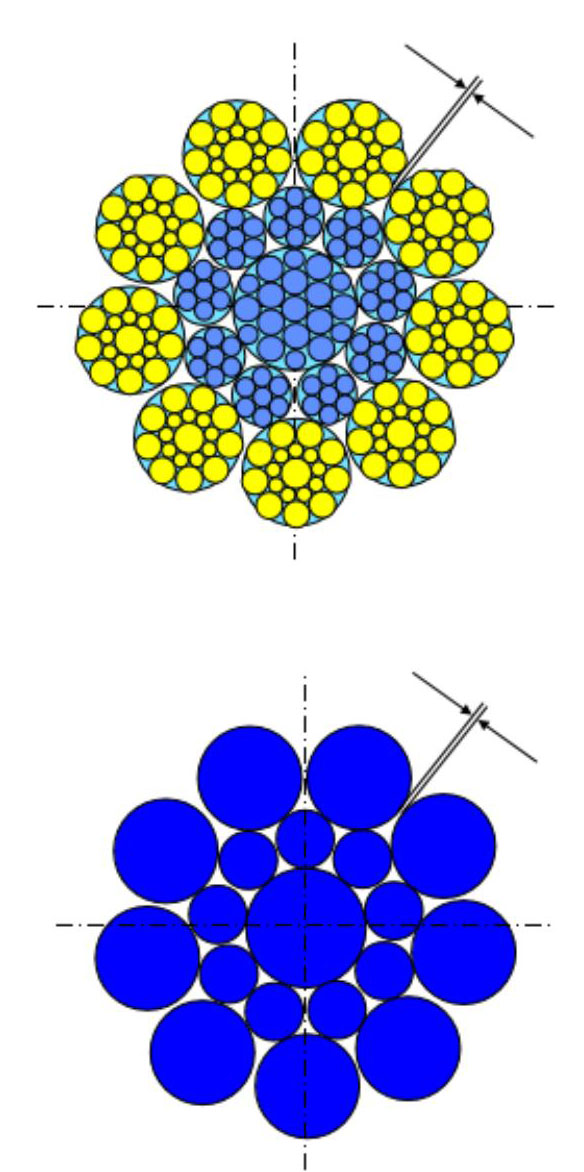

Wires of various diameters and grades are used to produce a strand.

Second step is to produce the strands and...

Second step is to produce the strands and the core

Third step is to close the strands over the core.

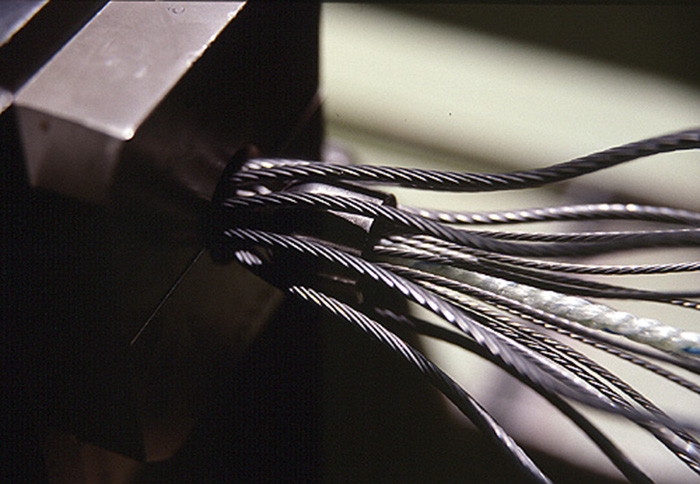

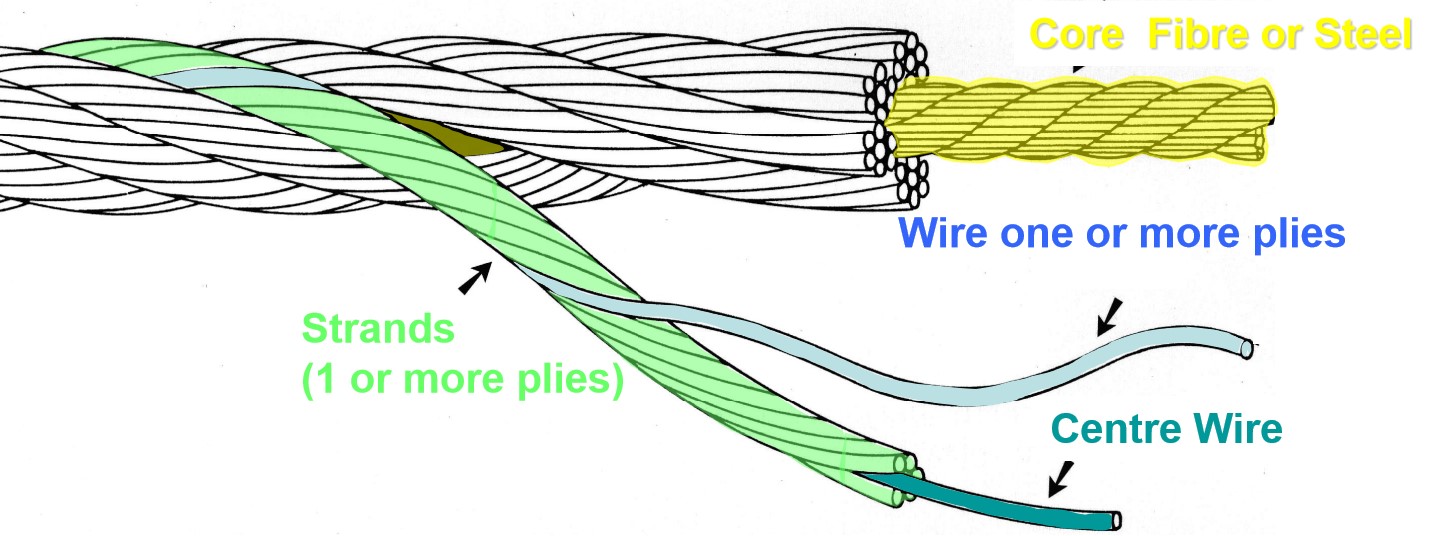

Wire rope

Parts of Wire rope

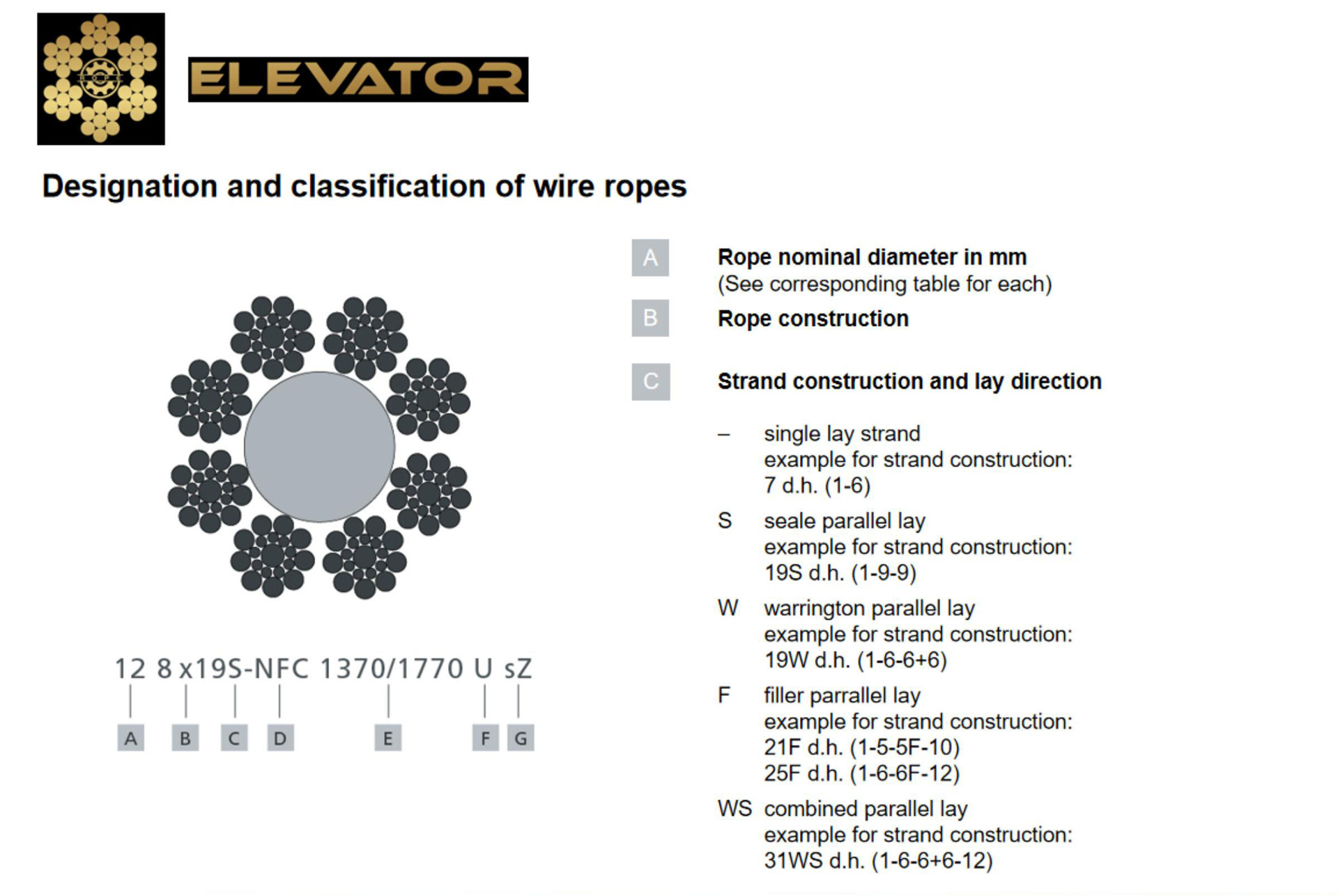

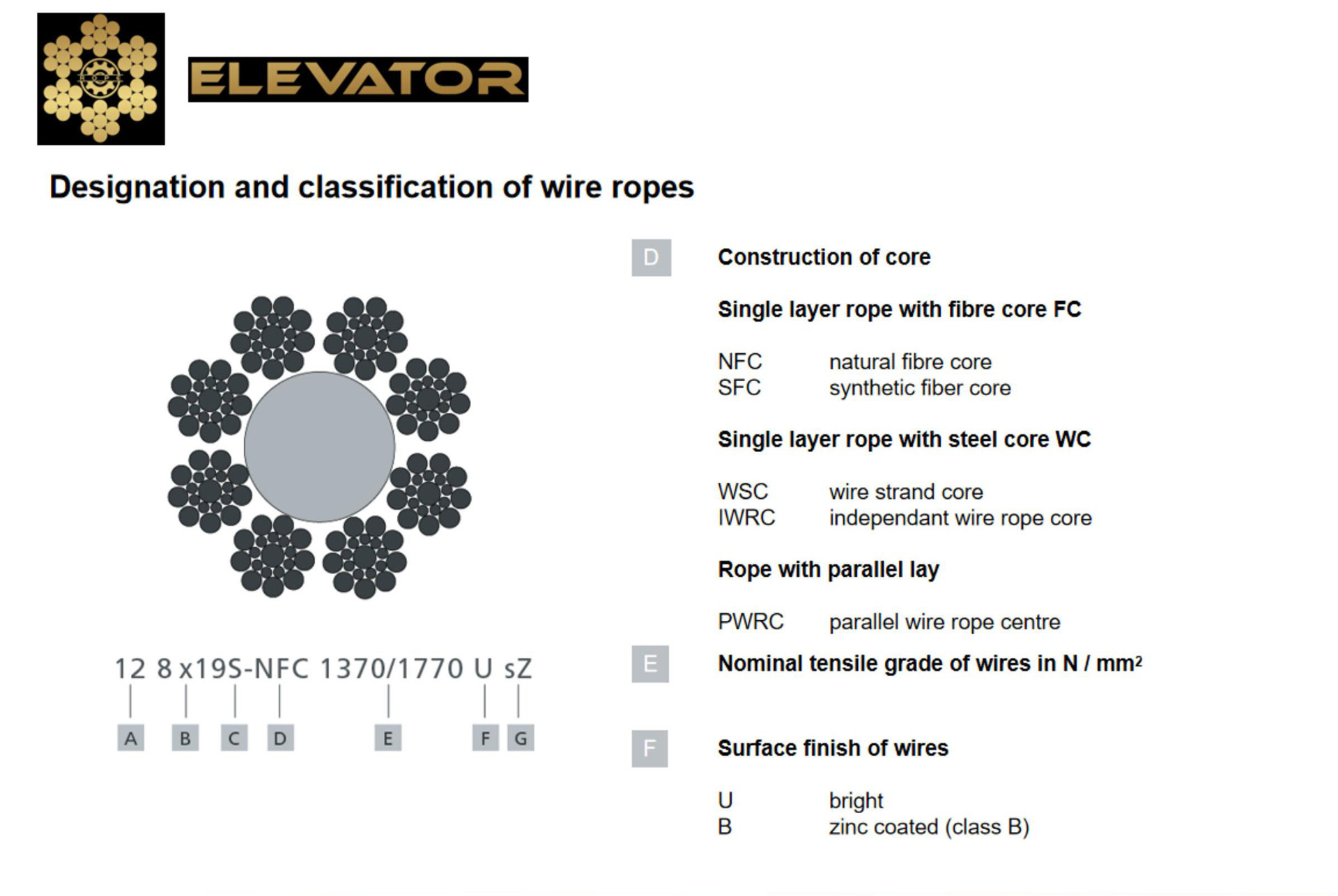

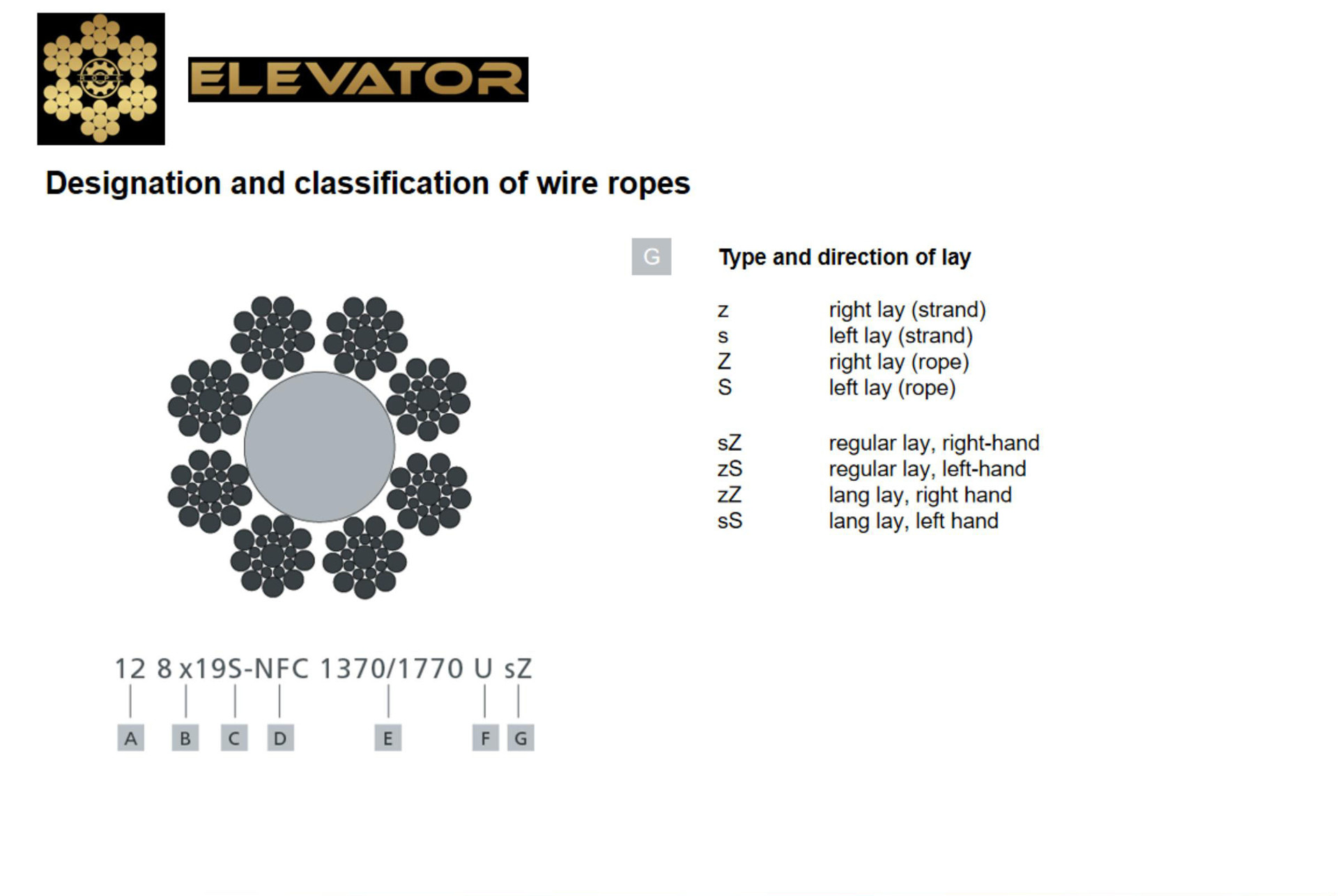

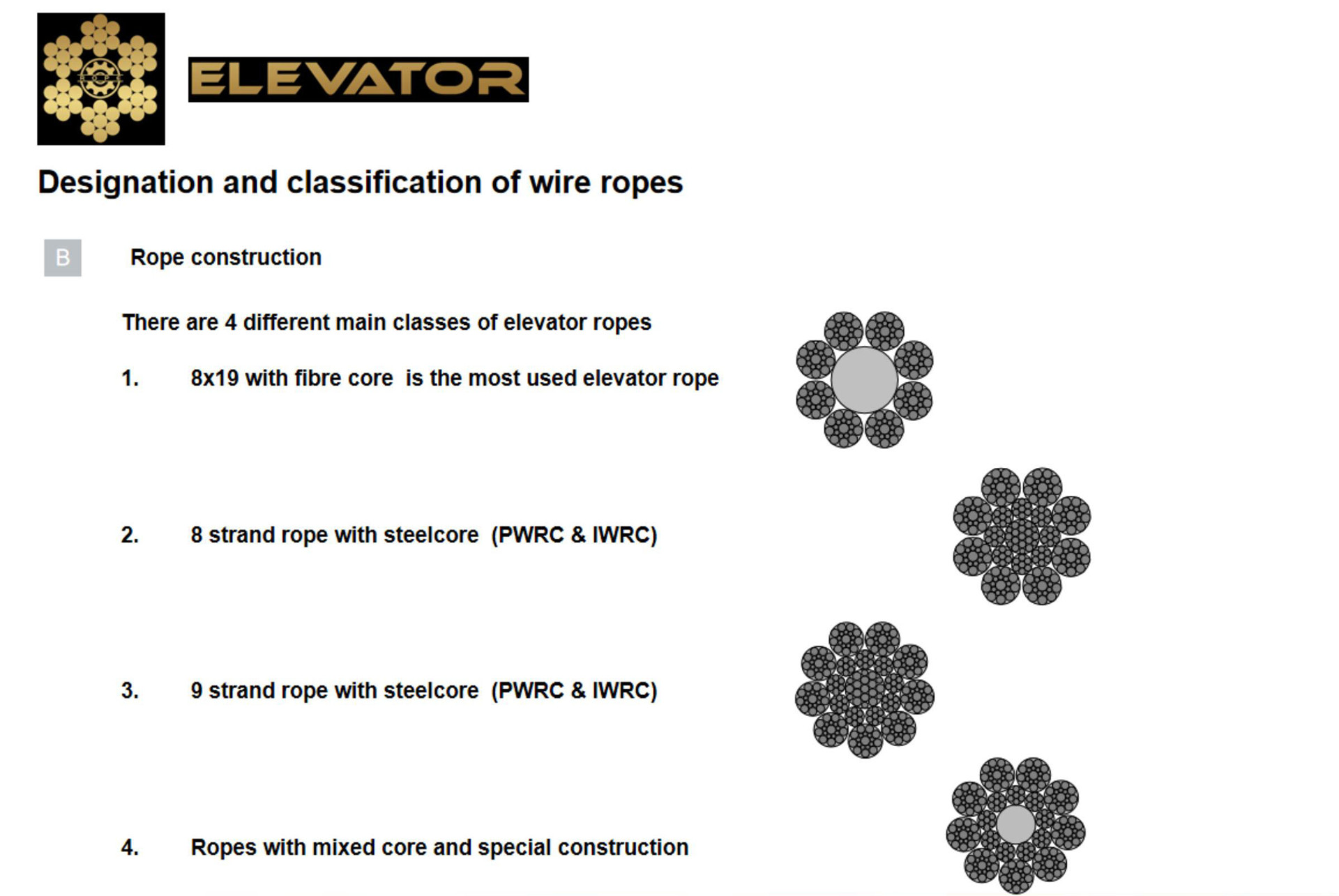

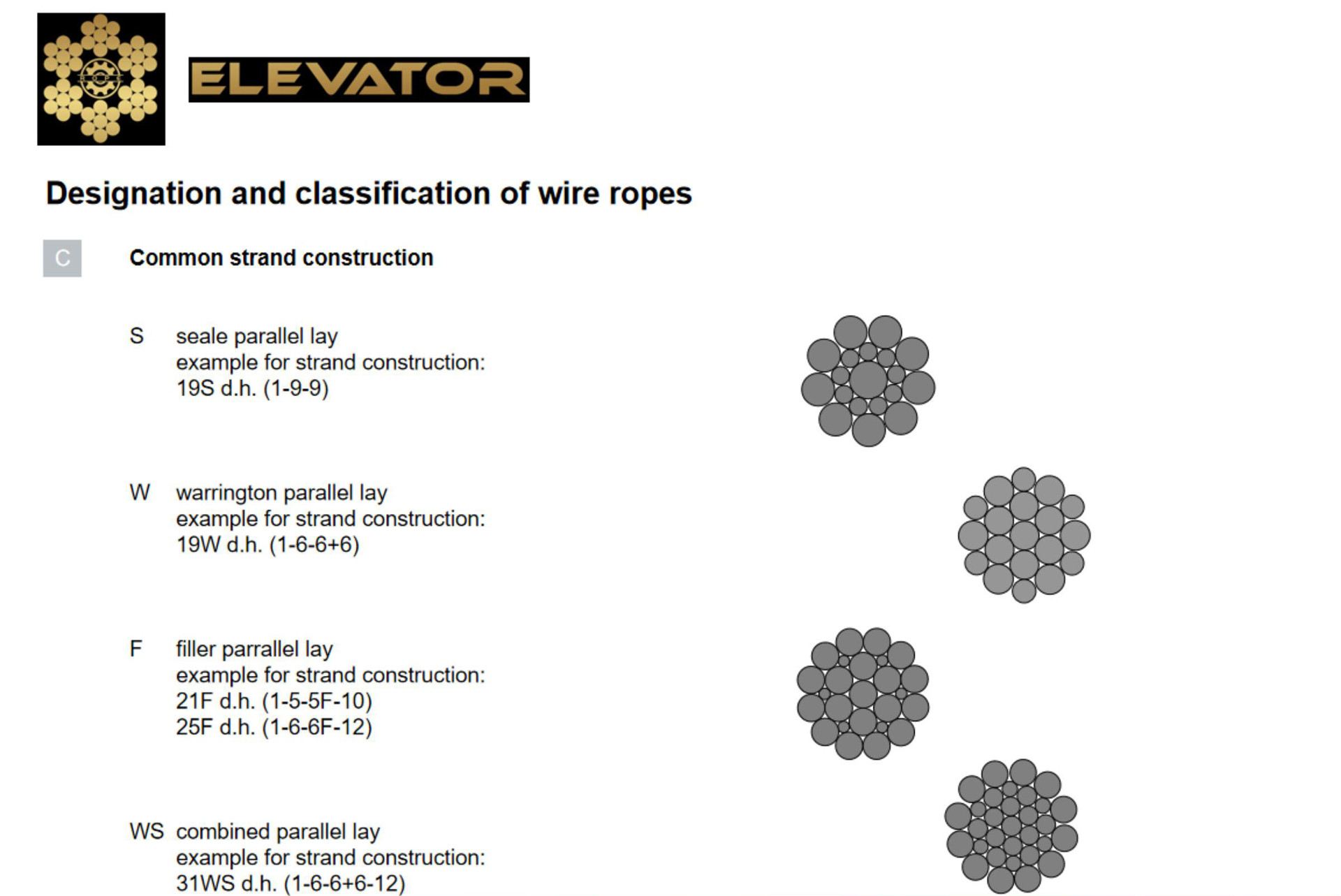

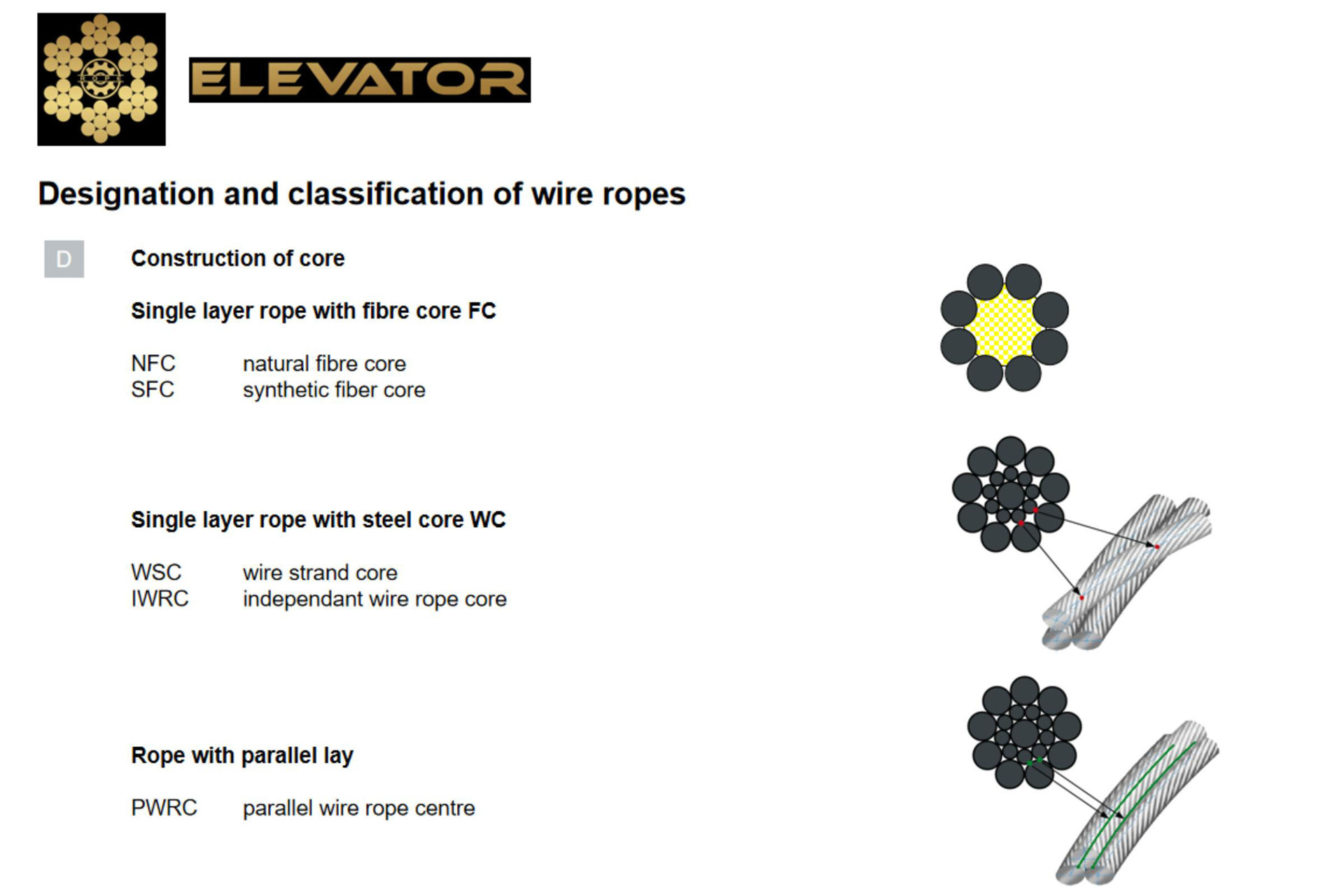

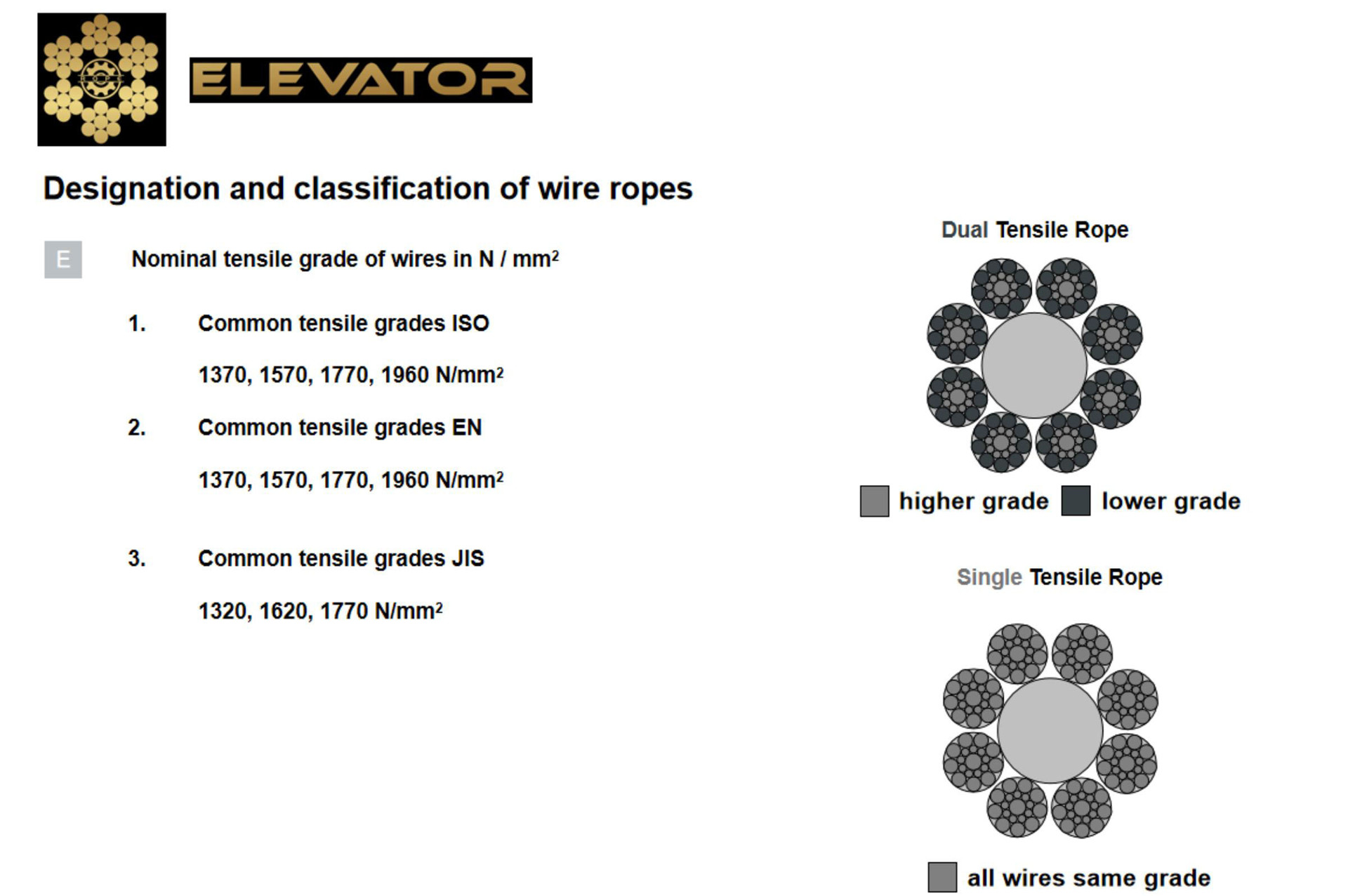

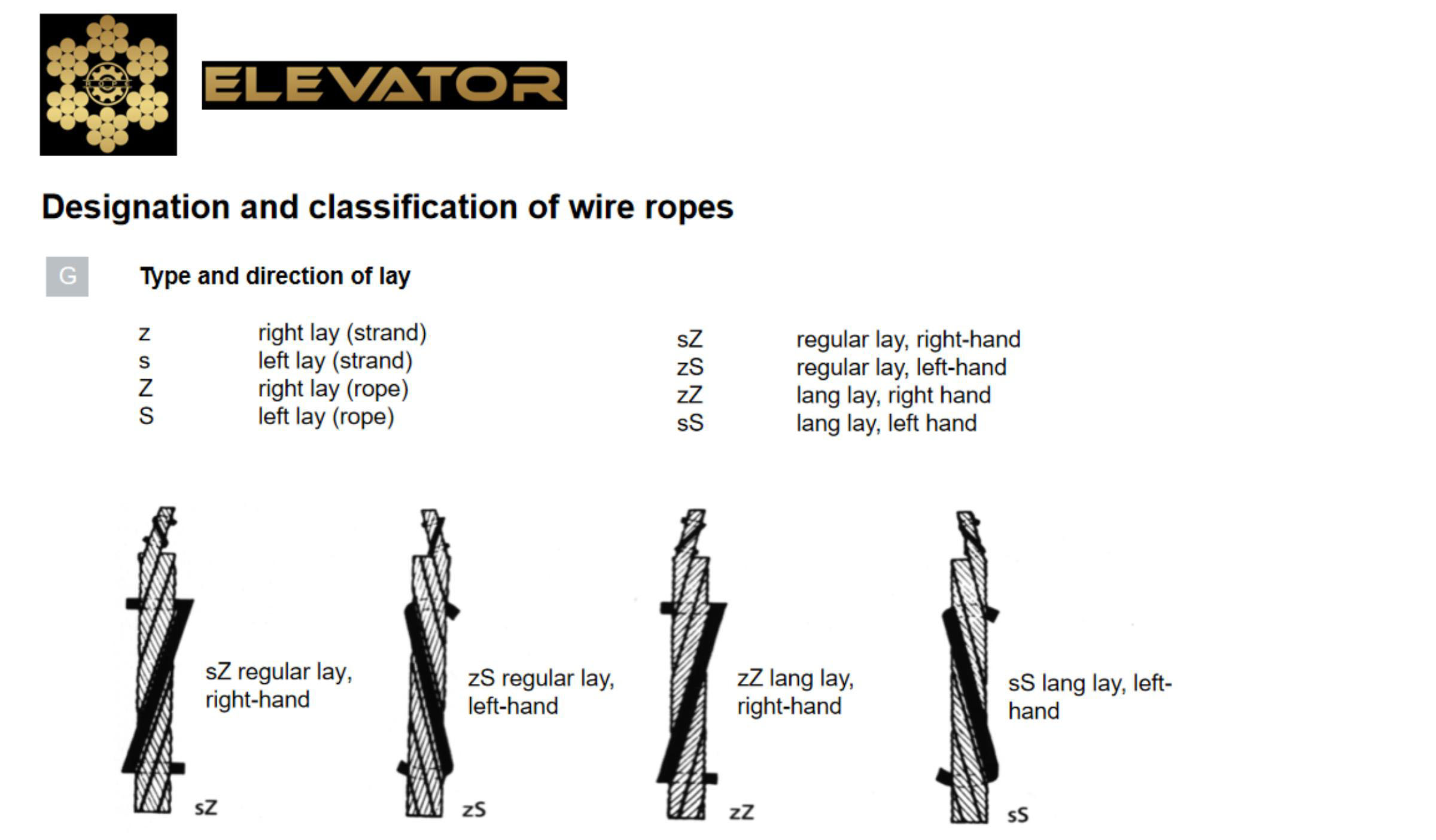

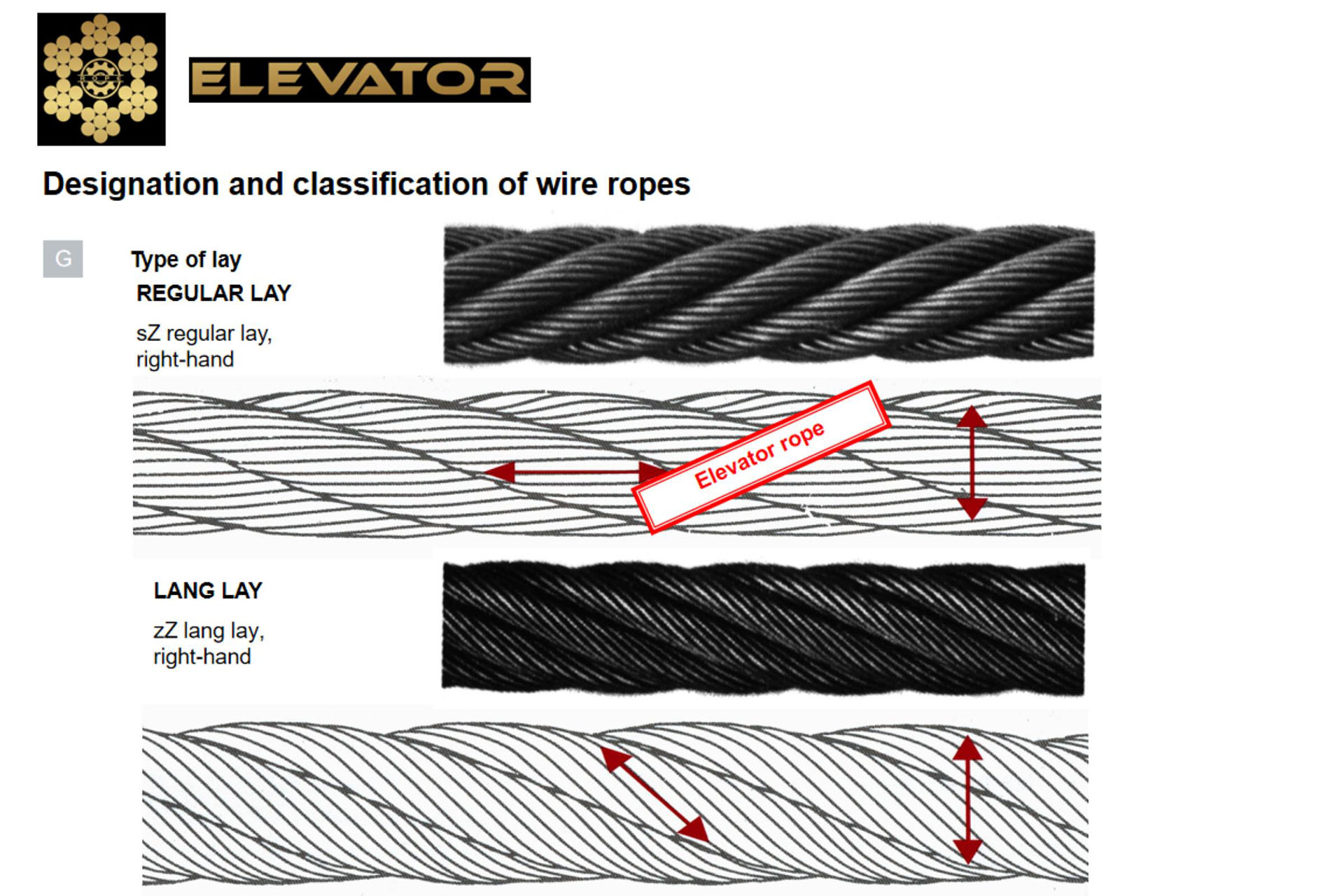

Designation and classification of wire ropes

Breaking Load

The breaking load is the force you need to break the rope.

We differ between 3 forces:

Minimum Breaking Load MBL

Is the force we quarantee

Calculated Breaking Load CBL

Is the force calculated out of the metallic area and the tensile strength of the wire

Tested Breaking Load

Is the tested force in a rupture test

The unit is N Newton or KN Kilonewton

Spinning factor / Spinning loss factor

The spinning factor is the experience factor which consider spinning loss during rope closing

The spinning loss factor is the difference beween the Calculated Breaking Load and the Tested breaking Load.

The size of the spinning loss factor is based on the Rope construction, the type of lay, the tensile grade of the wire.

The unit is %

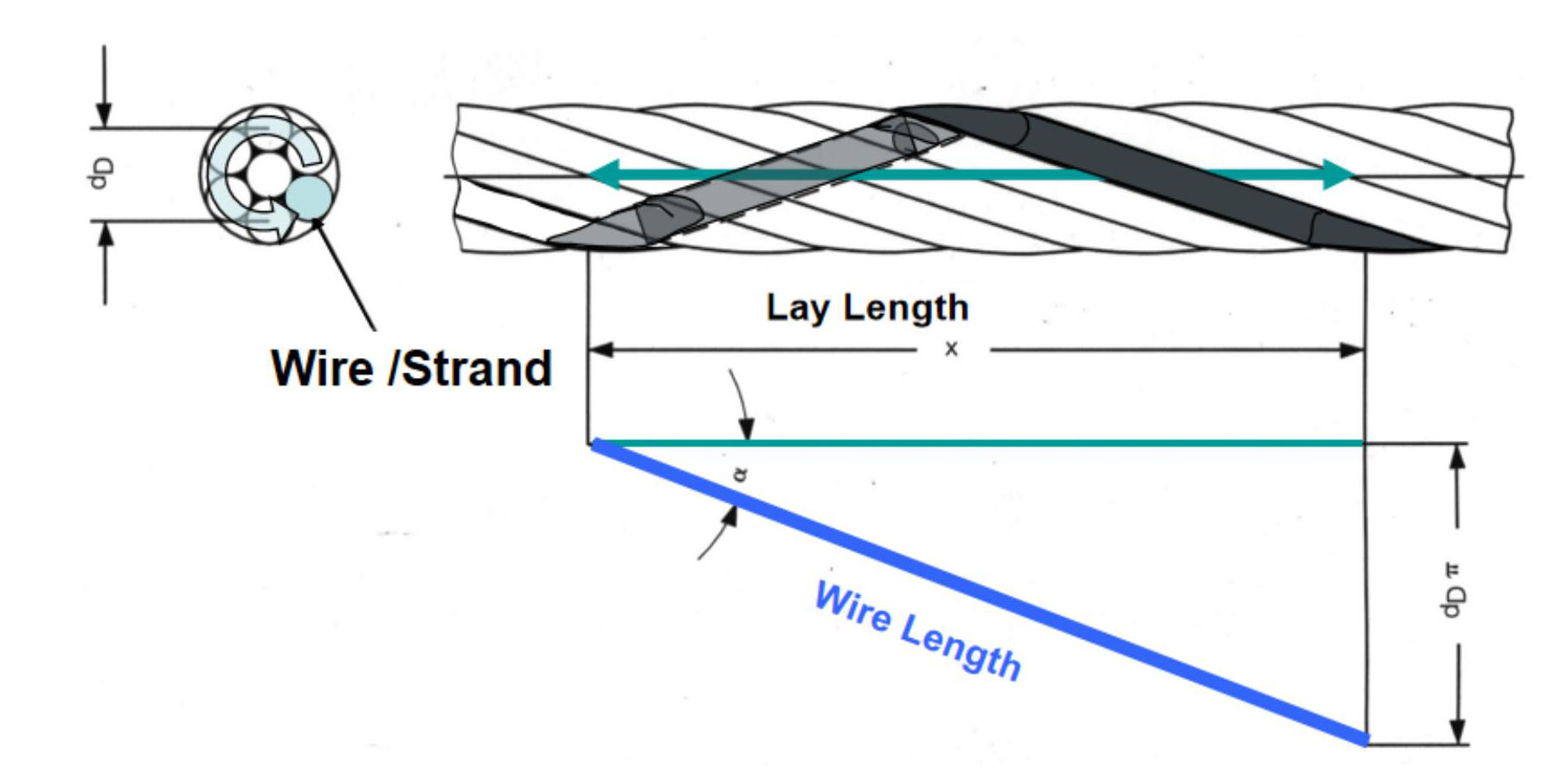

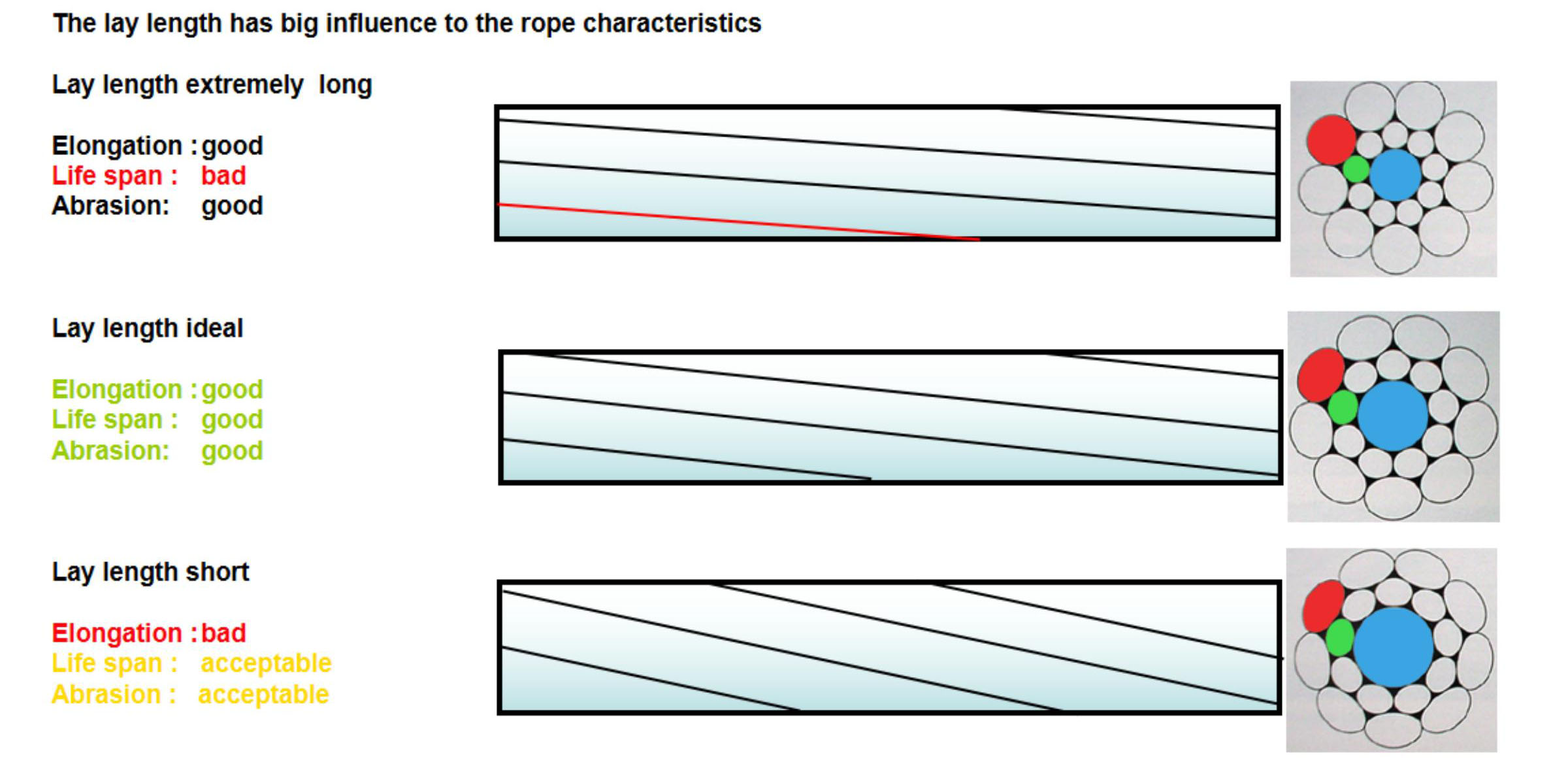

Lay length / Lay Angle

Lay Length

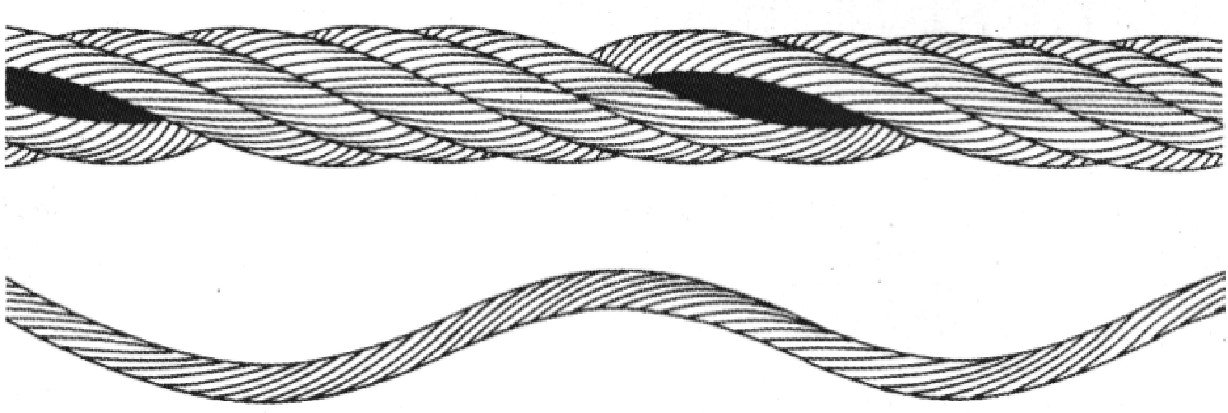

Pre-Forming

Pre forming is working step in the rope closing. This step is directly situated before the closing point .

The result of the pre forming is the Helix.

Pre forming has an influence of:

1) the setting

2) flexibility

3) degree of efficiency of the rope.

Ropes easier to handle

Longer life due to better load distribution

Resistant to kinking

Broken wires lie flat

Due to the post forming of the rope or strand, the individual strands or wires get their final position in the rope or strand.

Preforming

Pre-Forming

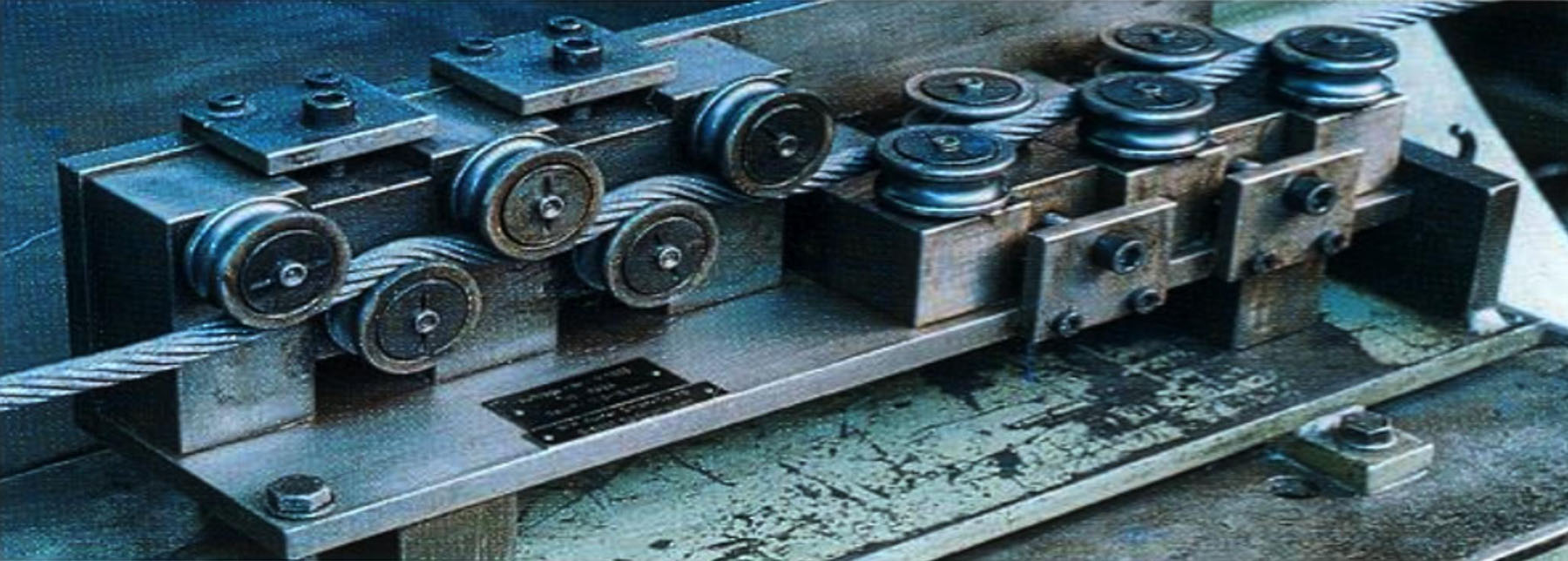

We differ to kind of clearance

Rope clearance

Strand clearance

Clearance means the geometrical defined gap between the single wire s in case of the strand, or between the strands in case of the rope.

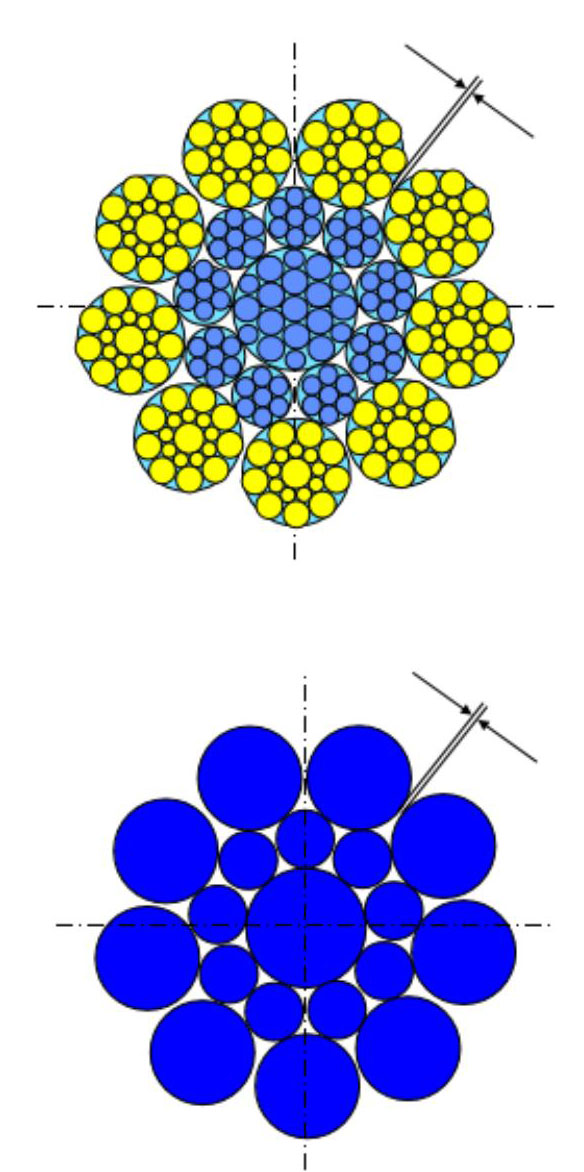

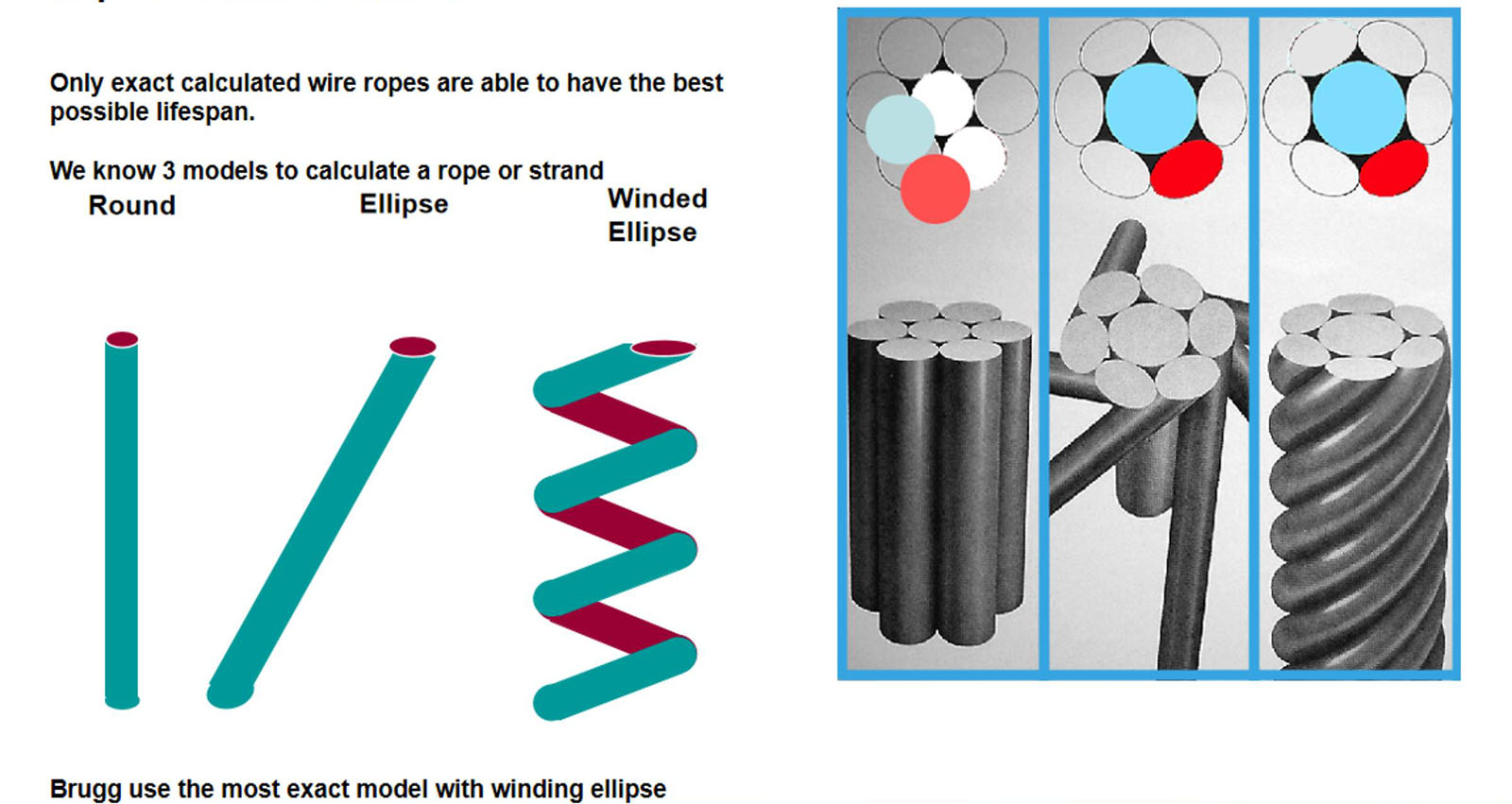

Only with exact calculated ropes and strands it is possible that the single components and the whole rope works perfect.

For different application areas the clearance have to be adjusted

Rope / Strand calculation

Post time: Feb-25-2022