Wire Rope Inspection

What to look for

• Broken Wires

• Worn or abraided wires

• Reduction in rope diameter

• Corrosion

• Insufficient Lubrication

• Rope tension

• Rope torsion

• Signs of crushing or mechanical damage

• Heat damage

• Kinks

• Bird caging

• Lay distortion

• Endfittings

Re-Lubrication

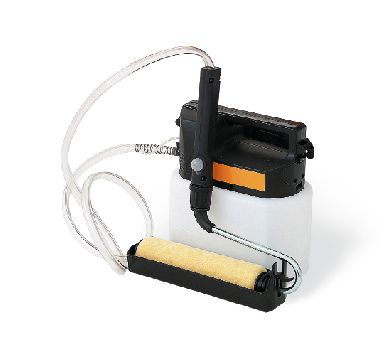

RLD – rope lubrication device

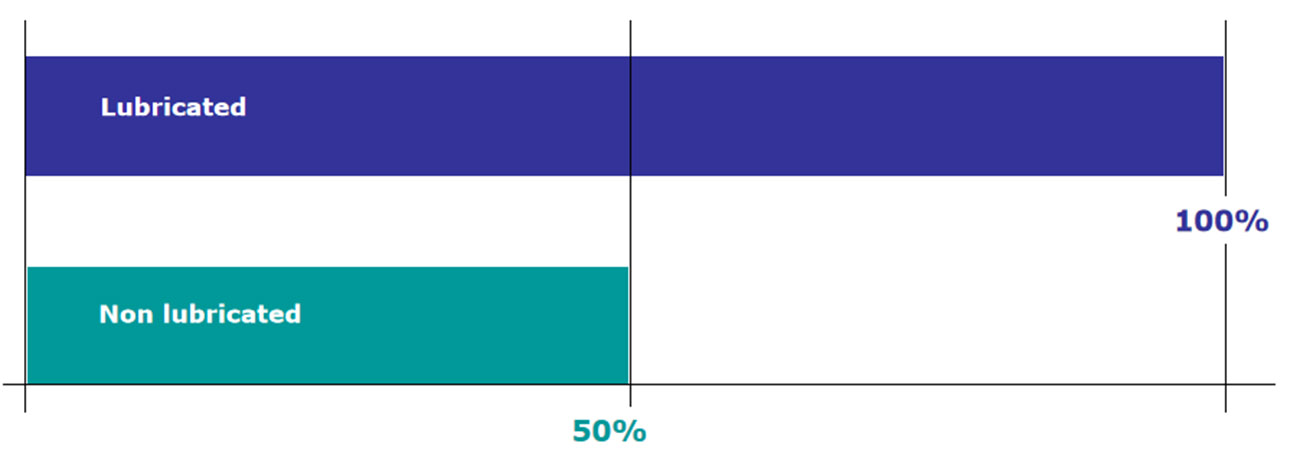

Well lubricated lasts longer

Personnel, installation and environment remain clean, while all elevator ropes of an installation are evenly lubricated. This operation is environmentally friendly, quick and easily achieved with the RLD – rope lubrication device.

Advantages

• no soiling of installation, environment and staff

• good proportioning

• environmentally friendly

• fast, simple and economical rope lubrication

Technical specifications

• power supply 220V or battery operation

• operation time with battery 15 hours

• roller width 430 mm • lubricant box volume

• suitable for VT LUBE

VT-Lube

Our rope lubricant VT LUBE has been especially developed for the relubrication of elevator ropes.

Advantages

• very good penetration characteristics – optimal reduction of internal rope friction

• outstanding creep properties for consistent distribution of the lubricant at the interior and exterior of the rope

• excellent protection against corrosion

• very good adhesive power to suit high rope velocities

• neutral against synthetic material (no swelling of plastic parts)

New Ropes

• New ropes are lubricated during the production process

• A long period of time between production and installation can lead to dry strands

• New ropes must be checked for sufficient lubricant

• If necessary, re-lubricate new ropes to double it’s lifetime!

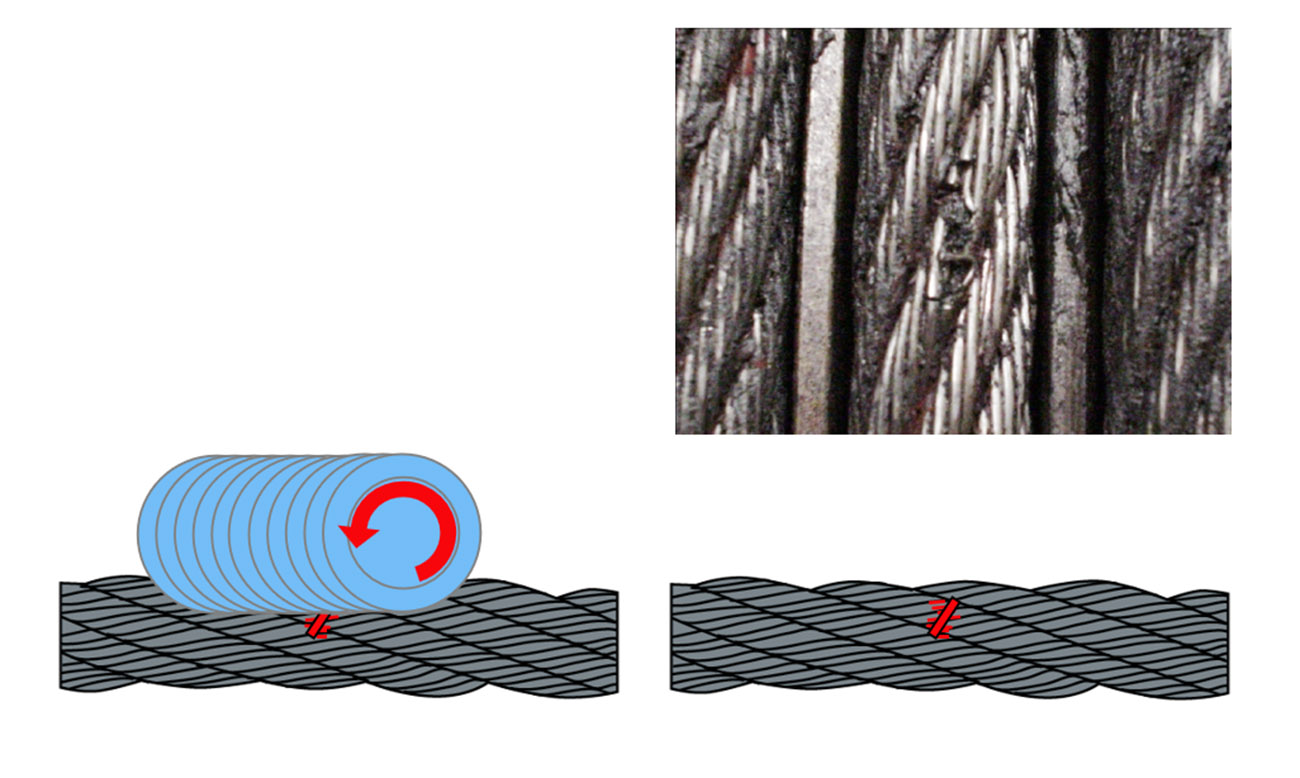

New ropes on new sheaves

• New sheaves are delicate for the rope during the first 100’s of cycles

• Sheave groves have partly an extremely hard surface

• Well lubricated ropes can reduce future damage to the rope

Rope lifetime

Example for corrosion due to insufficient lubrication

All elevator ropes of Brugg Wire Rope Inc. are lubricated during the production process. Since it is not under our influence, how long the ropes are stored until the mounting, we recommend checking the elevator ropes directly after their installation for sufficient lubrication and, if needed, lubricating again.

The further lubrication of the ropes should be effected as required. The ropes must however never be used in an unlubricated state.

A sufficient amount of lubricant has to be on the rope, it must not drip however from the rope during the ride of the lift.

We recommend the use of the special regreasing agent of Brugg or an equal lubricant. If you relubricate in time, you can increase the service life of the rope.

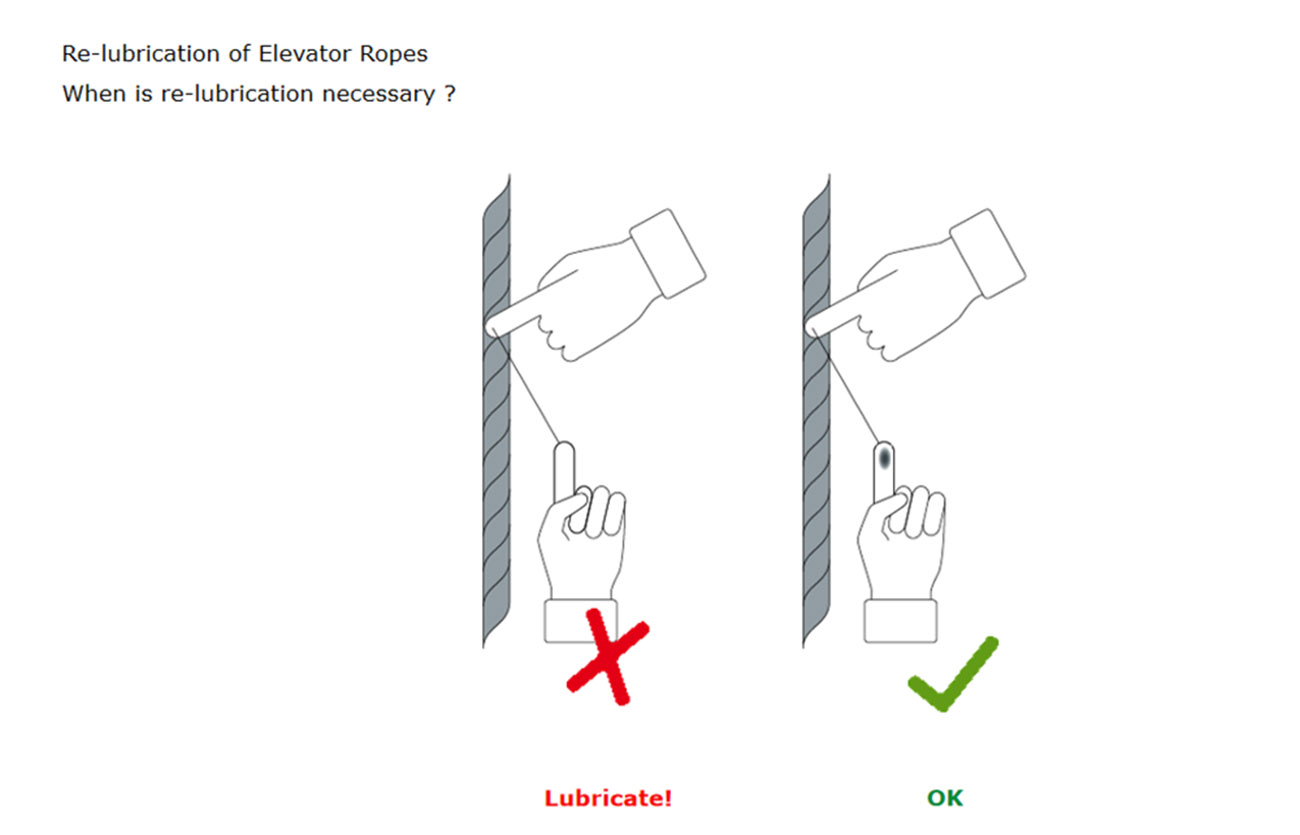

When is lubrication needed?

If there are no traces of lubricant left on your fingers when you touch the rope, you need to relubricate.

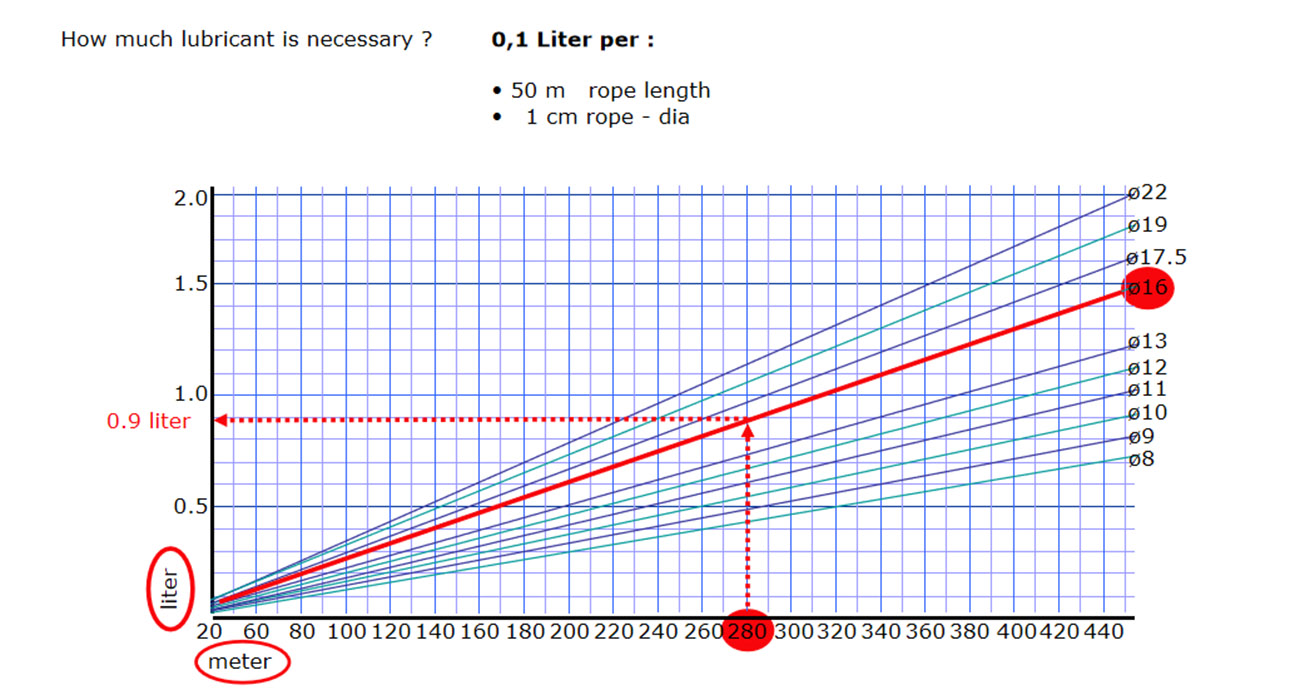

How much lubrication is needed?

0,4 litres of lubricant per centimetre wire rope diameter and 100 metres rope (relating to Brugg relubricant).

Principles for relubrication

You need to relubricate often, but sparingly. The lubricant has to be distributed on the complete rope surface. The relubrication should only be done on a clean rope (humidity, dust, etc.)

Demands on the relubricant

The relubricant has to be mixable with the mineral original lubricant. It has be able to penetrate well, the coefficient of friction μ ≥ 0,09 (-) (material pair steel /cast iron) has to be reached, so that the degree of traction is preserved.

Cleaning

If the rope surface is not „clean“ the lubricant can not penetrate into the rope. In case of a dirty rope the rope have to be cleaned before do the re-lubrication.

Re-Lubrication methods

● Paintbrush

● Decorators roller

● Oil can

● Spray

● Permanent lubrication systems ( be careful traction could be reduced)

Rope alignment

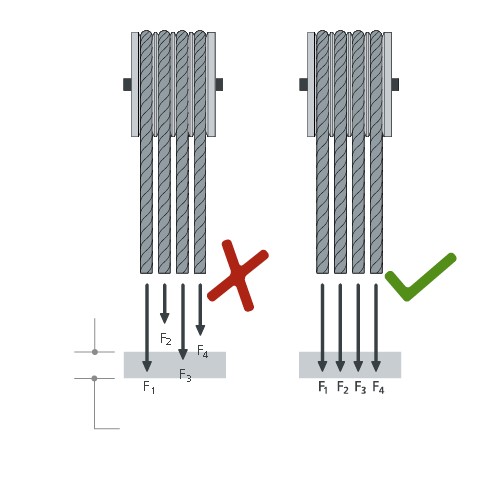

Rope tension

Tolerance zone 5% of F

Check the rope tension immediately after mounting with a suitable device, for example the RPM BRUGG. Make sure that all ropes in the rope group are evenly tensioned.

Repeat the rope tension check 3 months after the commissioning of the installation and later on in regular intervals.

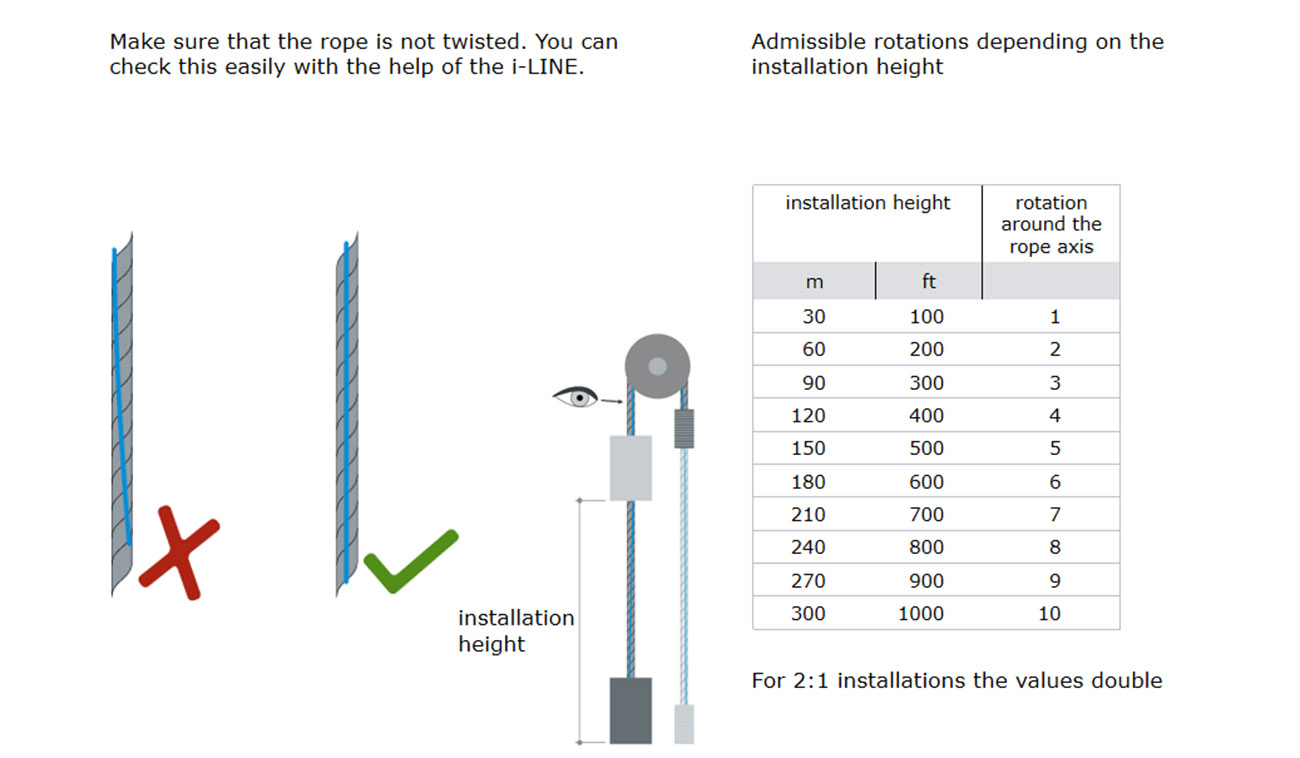

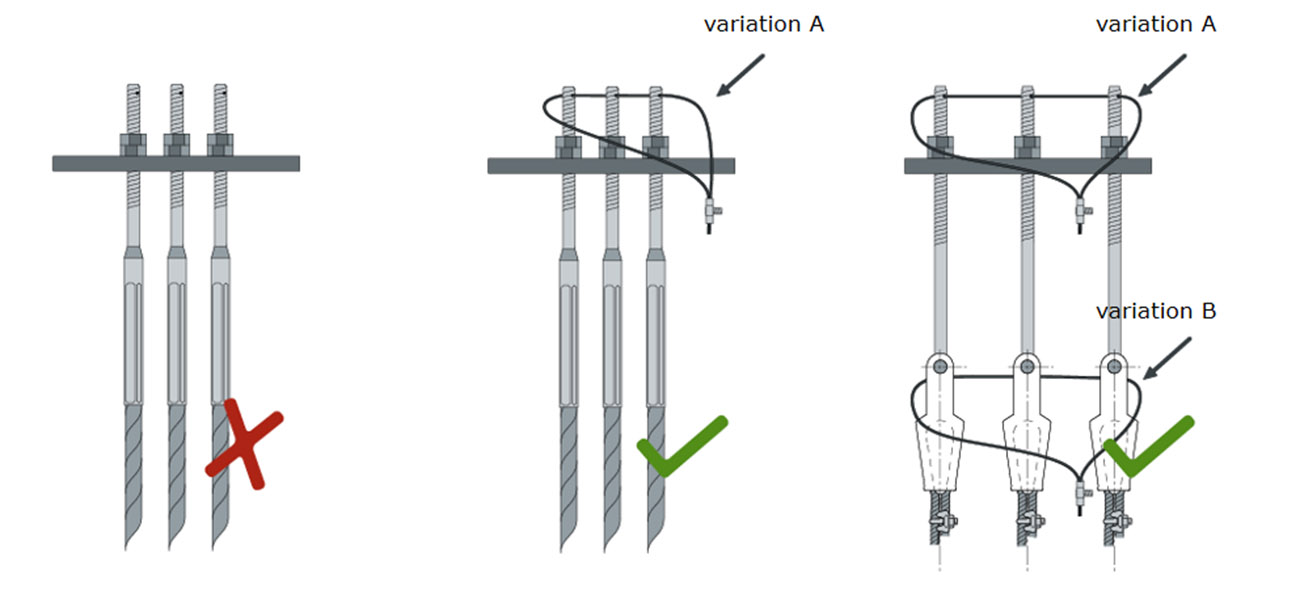

Anti rotation device

Ropes must be secured against rotation immediately after completion of installation, before operating the elevator.

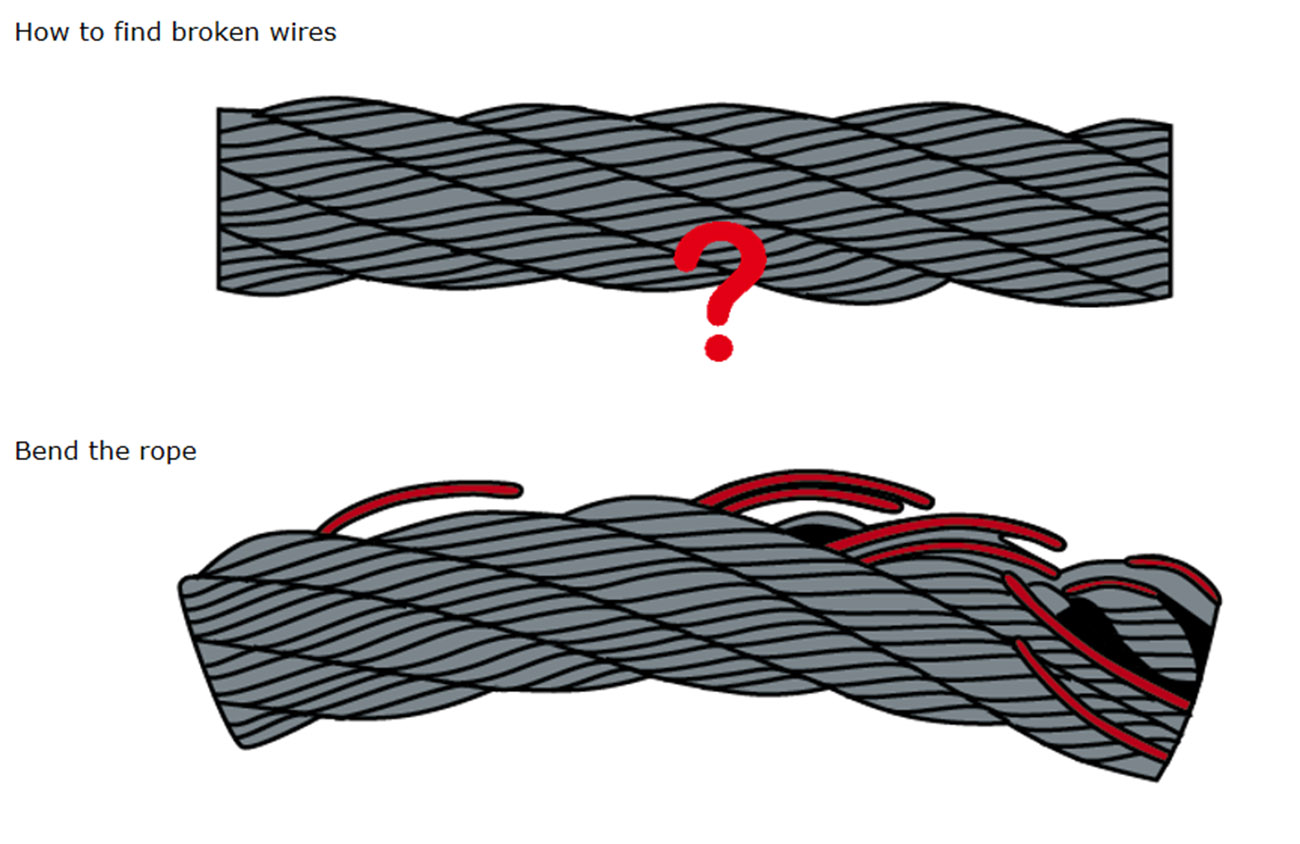

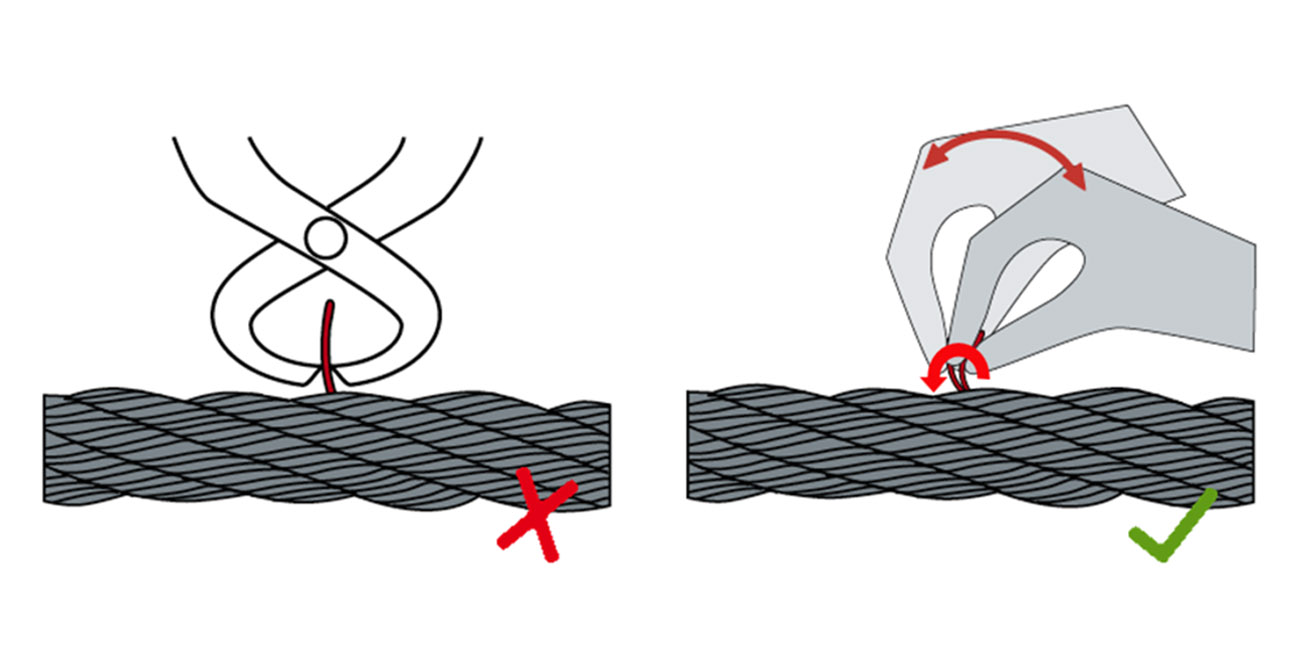

Broken Wires

How to remove broken wires correctly

Post time: Mar-18-2022